The precision machining industry is undergoing a major transformation under the influence of Industry 4.0. With the continuous advancement of new technologies, manufacturers are able to improve efficiency, enhance product quality, and reduce labor costs. In this article, MMK VIETNAM introduces three key technologies that are reshaping the future of precision manufacturing.

1. Industrial Robots – Boosting Productivity and Accuracy

One of the most prominent trends in today’s manufacturing world is the adoption of industrial robots in production lines. In particular, collaborative robots (cobots) like the FANUC CRX are gaining popularity thanks to their safety, flexibility, and ability to work directly alongside human operators.

Robots can now handle various tasks such as:

- Loading and unloading workpieces

- Assembling components

- Sorting and packaging

- Performing basic inspections

Compared to manual operations, robots significantly improve production speed, reduce human error, and maintain consistent precision over long working hours. More importantly, manufacturers can sustain productivity even when skilled labor is limited.

In Vietnam, many factories in sectors such as mechanical parts, electronics, and plastics have started investing in robot-integrated automation systems, paving the way toward smart manufacturing.

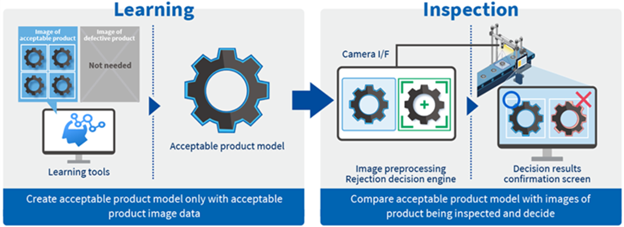

2. AI-Powered Quality Inspection – Smarter, Faster, More Accurate

In precision machining, surface quality, dimensional accuracy, and micro-defects are critical parameters. Traditional inspection methods often rely on human workers or manual tools, which are time-consuming and prone to errors.

Today, with the rise of Artificial Intelligence (AI), AI Vision systems powered by deep learning can now automatically detect product defects, such as:

Cracks, scratches, and deformations

Incorrect component placement

Out-of-tolerance measurements

A major advantage of AI is its learning capability – the more it inspects, the smarter and more accurate it becomes. These systems also allow manufacturers to collect inspection data, monitor trends, and trace back issues effectively.

At MMK VIETNAM, we provide intelligent visual inspection solutions from TOSHIBA, widely used in Japanese factories for their high-speed processing and superior accuracy.

3. Lights-Out Manufacturing – Unmanned Production for Maximum Efficiency

Another rising concept in the machining world is Lights-Out Manufacturing – where machines operate without human supervision during off-hours. These systems rely on a combination of:

CNC machines with remote connectivity

Automated material handling using industrial robots

Smart software for monitoring and alerts

Sensors and error detection systems

With this model, factories can continue production overnight or during holidays – maximizing output without increasing labor costs or overtime hours. In a time when skilled labor is scarce, unmanned machining solutions provide an effective and sustainable way to maintain production capacity.

Although Lights-Out Manufacturing requires initial investment, it delivers long-term benefits such as lower operational costs, higher efficiency, and minimized downtime.

Conclusion: Embracing Technology for a Competitive Edge

The rapid adoption of technologies such as robotics, AI inspection, and smart automation is driving significant progress in the precision machining industry. Manufacturers who stay ahead of these trends and choose the right partners and solutions will be well-positioned to stay competitive in a demanding global market.

At MMK VIETNAM, we are committed to supporting manufacturers in their digital transformation journey – from supplying cutting-edge machinery to delivering advanced automation and inspection solutions.

Tags: AI quality inspection, CNC automation, industrial robots, lights-out factory, precision machining technology, robotic integration in Vietnam, smart manufacturing